WiFi module – online connection with remote access to the machine, which allows for full real-time diagnostics, parameter correction and quick service response. Chocolate tank with water jacket and temperature sensor – precise adjustment of coating medium Servo motors – unique solution that rotate parts of a machine with high efficiency and great precision Mitsubishi Electric components and controllers Touch screen LCD with multilingual, intuitive menu You can enter your settings and save them on the SD card

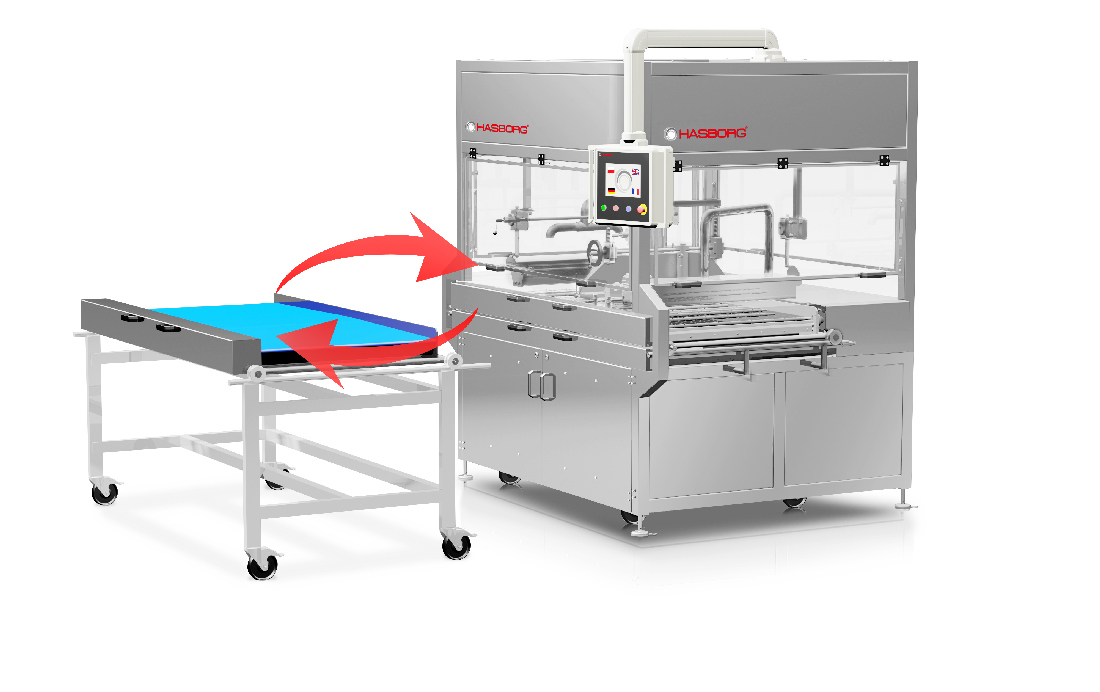

The design of enrobing machine allows quick and easy exchange of the work table. Thanks to the trolley, the entire operation is maximally simplified. We offer two types of work tables: mesh table with vibration (shaking system) and conveyer belt . This solution gives you many possibilities to work with different products depending on current needs, and make cleaning process much easier.

Movable tank for coating medium

Machine is equipped with chocolate tank + water jacket and automatic temperature control. Thanks to the possibility of sliding the chocolate tank out of the machine - filling, changing the coating medium, washing - now become much easier and significantly reduces downtime at work.

Bottom enrobing

The bottom enrobin function is to cover the underside of the product with coating unit. The product transported on the mesh conveyor "flows" over the molten coating. Enrobing height is precisely adjusted depending on the needs.

Enrobing of entire product

Top and botton enrobing function makes the product fully covered with coating medium.

Decorating unit

The enrobing machine can be equipped with a highly advanced ZIG ZAG decorator module, which gives a wide range of possibilities for decorating products. This module can be combined with the bottom enrobing system

Wire-mesh vibration (shaking system)

The mesh conveyor is equipped with a shaking system, which gives you a possibility to wire-mesh vibration and accelerate the flow of coating from the bottom side of product.

-9222.jpg)

Product examples: